Tapasya's Fluid Bed Equipment (FBE) is

specially designed unit for agglomeration and

simultaneous drying for top spray granulation

conforming to the international quality norms

and with all latest features incorporated. Built

with a working pressure of 2 Bar at 80 degree C,

the drying capabilities of our FBDs are enhanced

by 18 - 20%, resulting in lesser drying time

and uniform fluidization. Air Handling System

is specially designed for evenly distribution

of Heat to the material to be dried in order to

supply the latent heat required for vaporization

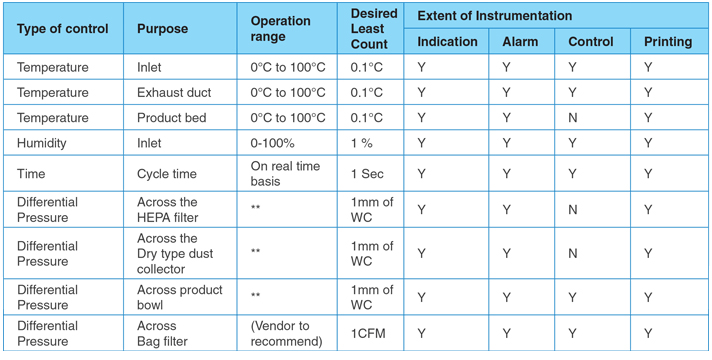

of the moisture. The fully automated system

is designed to achieve robust formulation and

stringent cGMP compliance.

Tapasya's Fluid Bed Equipment (FBE) is

specially designed unit for agglomeration and

simultaneous drying for top spray granulation

conforming to the international quality norms

and with all latest features incorporated. Built

with a working pressure of 2 Bar at 80 degree C,

the drying capabilities of our FBDs are enhanced

by 18 - 20%, resulting in lesser drying time

and uniform fluidization. Air Handling System

is specially designed for evenly distribution

of Heat to the material to be dried in order to

supply the latent heat required for vaporization

of the moisture. The fully automated system

is designed to achieve robust formulation and

stringent cGMP compliance.